Hospital Bed Manufacture: A Complete Guide for you.Hospital Beds are essential components in healthcare facilities, ensuring patients receive the proper care and comfort during their recovery. As the demand for advanced, customizable, and durable hospital beds continues to rise globally, understanding the intricacies of hospital bed manufacturing has become more important than ever. This comprehensive guide will walk you through the entire process of hospital bed manufacturing, from design and material selection to production and quality control. Whether you’re a healthcare professional, procurement specialist, or simply curious about the process, this guide will provide valuable insights into how modern hospital beds are made and the key considerations that impact their functionality, safety, and patient comfort.

Design & Concept Development: The Blueprint of Comfort and Functionality

The design and concept development of Hospital beds is a critical phase in creating a comfortable and functional environment for patients. At Grace Medy, this phase begins with a thorough informational gathering process, where designers conduct state-of-the-art reviews, observe usage patterns, interview users, and employ tools like Quality Functional Deployment (QFD). These efforts ensure that the design not only meets the specific needs of both patients and healthcare professionals but also aligns with industry standards and user expectations.

Functional Decomposition and Ergonomic Considerations

The first step in the design process involves functional decomposition, where the bed’s primary functions are broken down into smaller, manageable subfunctions. This allows the Grace Medy design team to identify essential features such as adjustable head and foot positions, safety rails, and easy actuation mechanisms. By utilizing tools like the morphological matrix, the team narrows down potential solutions, focusing on features that are backed by technical knowledge and the latest ergonomic research.

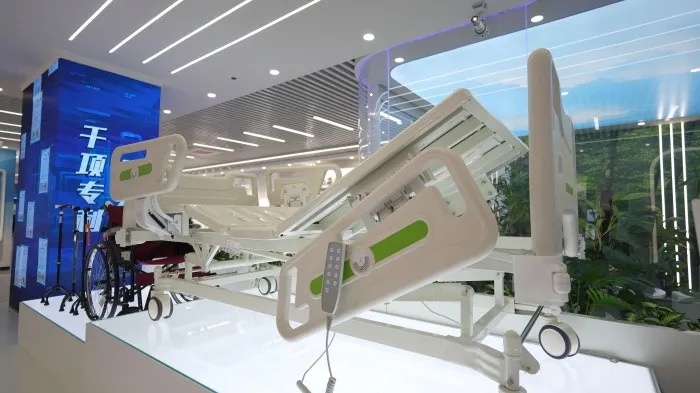

Modern hospital beds from Grace Medy also prioritize ergonomic design to support optimal patient comfort and recovery. Adjustable features, such as head and foot positioning, cater to the personalized needs of patients, ensuring they can rest in a position that promotes healing and minimizes discomfort.

Pressure-Relief and Safety Features

One of the most important aspects of a hospital bed’s design is the integration of pressure-relief systems. Grace Medy beds are equipped with advanced mattresses featuring pressure-relieving foam and adjustable firmness to reduce the risk of pressure ulcers, which can significantly affect a patient’s comfort and recovery time.

Additionally, safety and security are paramount. The bed’s frame must be sturdy, and features like reliable side rails and adjustable settings are necessary to prevent falls, especially for patients with limited mobility. Grace Medy’s commitment to high safety standards ensures that their beds provide both security and comfort, meeting the needs of healthcare providers and patients alike.

Ease of Use and Technological Integration

Grace Medy also excels in designing beds that are easy to use and adjust. Manual beds incorporate levers and drive screws that require minimal force, enabling healthcare professionals to adjust the bed efficiently while maintaining patient safety. For higher-tech options, Grace Medy integrates advanced features such as environmental sensors that automatically adjust the bed to optimize comfort based on room conditions like temperature, light, and noise. Additionally, data logging capabilities allow the bed to record essential health data, which can be integrated into hospital systems for improved long-term monitoring and clinical decision-making.

Durable Materials and Mobility

The materials used in Grace Medy hospital beds are chosen for their durability, comfort, and ease of maintenance. Beds are constructed from high-quality materials with easy-to-clean surfaces, ensuring longevity and minimal upkeep. Furthermore, to enhance mobility, Grace Medy beds are equipped with robust wheels and locking mechanisms, allowing for easy repositioning and secure placement. These features not only enhance patient safety but also improve the efficiency of healthcare workers in providing care.

Through the careful design and integration of these key features, Grace Medy ensures that their hospital beds offer the optimal balance of patient comfort, safety, and functionality, supporting both recovery and the overall healthcare experience.

Raw Material Acquisition

The acquisition of raw materials is a critical phase in hospital bed manufacturing, and at Grace Medy, great attention is given to sourcing materials that meet the highest medical standards. The materials used in their hospital beds are carefully selected to ensure safety, durability, and reliability in healthcare settings, where the stakes are especially high.

Medical-Grade Steel and Aluminum

Grace Medy hospital beds are constructed with frames made from premium medical-grade stainless steel and aluminum. These materials are chosen for their superior corrosion resistance and strength. CNC-grade steel and aluminum are commonly used at Grace Medy, ensuring precision and accuracy during the manufacturing process. This choice of material guarantees that the bed frames provide the structural integrity required for long-lasting, high-performance hospital beds.

Antimicrobial, Fire-Retardant Fabrics

The mattress covers used in Grace Medy hospital beds are made from antimicrobial and fire-retardant fabrics, prioritizing both hygiene and patient safety. These materials are designed to prevent the growth of harmful bacteria, contributing to a sterile environment in clinical settings. Additionally, the fabrics meet strict fire-safety standards, which are essential for maintaining patient safety in healthcare environments. Grace Medy ensures that these high-performance materials are not only functional but also contribute to a safer, more comfortable patient experience.

Electronic Components

For their advanced hospital beds, Grace Medy incorporates high-quality electronic components, including actuators, motors, and control modules, which allow for motorized position adjustments and integrated patient monitoring systems. These components are sourced from specialized manufacturers to ensure their functionality, compatibility, and reliability. This integration of advanced technology helps provide a higher level of care and convenience for both healthcare professionals and patients.

Other Materials

The bed platform, structure, and legs of Grace Medy beds are typically constructed from cold-rolled steel, coated with electrostatic powder coating for enhanced durability and ease of maintenance. These materials are not only strong and long-lasting but also ensure the bed is easy to clean, supporting the hospital’s hygiene standards. By using high-quality materials, Grace Medy ensures that their beds are both durable and easy to maintain, which is vital for busy healthcare environments.

Compliance and Durability

At Grace Medy, all raw materials used in the production of hospital beds comply with stringent healthcare regulations, ensuring they meet international standards for safety and durability. The materials are designed to withstand continuous use and heavy loads, ensuring both the structural integrity of the bed and the safety of patients. Grace Medy’s commitment to sourcing high-quality, compliant materials guarantees that their hospital beds provide both the longevity and reliability needed in modern healthcare facilities.

Laser Cutting & CNC Stamping: Shaping Components with Precision

Laser cutting and CNC stamping are vital manufacturing techniques in the production of hospital bed components, ensuring the high precision and accuracy required for creating intricate and durable parts. At Grace Medy, these advanced processes are employed to maintain the stability, functionality, and safety of their Adjustable hospital beds, ensuring that each bed meets the stringent demands of modern healthcare environments.

Laser Cutting: Precision and Accuracy in Medical Components

Laser cutting is a high-precision method used to cut medical-grade materials like stainless steel, aluminum, and other alloys, essential for creating the detailed parts required for adjustable hospital bed frames. Grace Medy relies on laser cutting technology to ensure that each component is crafted with exacting standards, maintaining the structural integrity of the bed.

- High-Precision Process: Laser cutting technology at Grace Medy ensures that metals are precisely cut into intricate shapes, allowing parts to fit together seamlessly and maintain the bed’s overall stability.

- Material Compatibility: Grace Medy’s laser cutting process accommodates a wide range of materials, including advanced alloys like MP35N (cobalt-chrome steel), Nitinol, and titanium, which are sometimes used in hospital bed components. Special care is taken to manage thermal build-up and prevent imperfections, especially in sensitive materials like titanium.

- Precision and Accuracy: The laser cutting process ensures each part is manufactured with high precision, meeting tight tolerances necessary to preserve the bed’s functionality and stability, key elements in creating a reliable hospital bed.

CNC Stamping & Bending: Forming Metal Components with Consistency

CNC stamping and bending are integral to shaping the metal components that form the bed frame, ensuring consistency and precise tolerances for every part. These technologies are crucial for Grace Medy in producing hospital beds that are both functional and ergonomic, offering the necessary strength and flexibility.

- Uniformity and Tolerances: CNC machines at Grace Medy shape and bend metal to exact specifications, maintaining uniformity across all components. This consistency ensures that the hospital beds operate efficiently and meet the ergonomic needs of patients.

- Forming & Tooling: Grace Medy uses CNC technology to create custom shapes, holes, and bends in metal components, ensuring that all parts fit together seamlessly and contribute to the bed’s strength, functionality, and overall design.

Applications and Benefits in Hospital Bed Manufacturing

Laser cutting and CNC stamping are indispensable in the production of Grace Medy’s hospital beds, making them flexible, durable, and adaptable to diverse patient needs.

- Adjustable Frames: Laser cutting is particularly important in crafting adjustable frames, balancing strength, comfort, and compliance with healthcare regulations. Grace Medy’s adjustable frames are designed to accommodate various patient needs while ensuring long-term durability.

- Medical Components: The precision of laser cutting also makes it ideal for producing small medical device components, such as tubes and other intricate parts, ensuring dimensional accuracy and the required functional features for optimal performance.

In conclusion, Grace Medy’s use of laser cutting and CNC stamping technologies ensures the manufacturing of reliable, durable, and safe hospital bed components. These advanced processes play a crucial role in ensuring the beds provide both safety and comfort, meeting the rigorous standards required in healthcare settings. With these techniques, Grace Medy delivers high-quality hospital beds that support patient care, recovery, and well-being.

Welding & Frame Assembly: Establishing Structural Integrity

Welding plays a crucial role in establishing the structural integrity of hospital beds, ensuring that the frame can withstand the constant stress and weight in a healthcare environment. At Grace Medy, this process is vital for creating a strong, stable frame that guarantees the bed’s durability over time.

The Role of Robotic Welding in Frame Assembly

Grace Medy employs robotic welding to create precise, secure joints, eliminating weak points in the bed frame. This automated process ensures uniformity and consistent quality across all units, significantly enhancing the strength and longevity of the hospital beds.

Quality Control and Testing

After welding, each joint undergoes rigorous inspection at Grace Medy. Ultrasonic and magnetic particle testing are used to detect any potential flaws in the welds, ensuring structural integrity. This is crucial for meeting healthcare standards and guaranteeing the bed’s safety for patient use.

Frame Subassembly and Modular Design

For hospital beds with multiple sections, Grace Medy uses a modular design approach. Components are pre-assembled into modular units, allowing for efficient final assembly while maintaining tight quality control at every stage. This ensures all parts fit together perfectly for seamless assembly.

CNC Machines for Precision and Uniformity

In the initial assembly stages, Grace Medy utilizes Computer Numerical Control (CNC) machines to shape components with exacting tolerances. This precision ensures perfect alignment, contributing to the bed’s overall stability and functionality.

Load Testing and Structural Stability Verification

Once assembled, Grace Medy hospital beds undergo rigorous load and stress testing to verify their load-bearing capacity and structural stability. These tests simulate real-world conditions, ensuring the bed can safely support various patient weights and daily use.

Electrical Safety for Motorized Beds

For motorized hospital beds, electrical safety is a priority at Grace Medy. Comprehensive electrical checks ensure proper grounding and insulation, meeting all safety standards. This guarantees the harmonious functioning of the bed’s mechanical and electrical systems without risk to patients or healthcare staff.

Compliance with Healthcare Standards

hospital bed manufacturers include Grace Medy must adhere to strict regulatory standards, including those set by the ISO and FDA. Compliance ensures the beds meet necessary healthcare regulations for structural stability, infection control, and overall safety. This rigorous approach guarantees that the beds are safe and reliable for healthcare settings.

Modular Assembly Line

The modular assembly line plays a vital role in the efficient production of hospital beds, ensuring high-quality manufacturing while maintaining strict control over each step of the process.

- Nondestructive Testing (NDT): Ensures each weld and component is free from defects.

- Compliance: Testing ensures that the final product adheres to stringent healthcare regulations.

In conclusion, the modular assembly line is crucial for the high-quality, efficient production of hospital beds, ensuring that each unit meets rigorous standards for durability, safety, and functionality.

Quality Control & Compliance Testing: Ensuring Safety and Reliability

Summary

In conclusion, the manufacturing of hospital beds is a meticulous process that balances precision, safety, and comfort. From design and material selection to rigorous testing and quality control, every step ensures that these essential devices meet the highest standards. As the healthcare industry evolves, the continuous innovation in hospital bed design promises improved patient care and recovery experiences for all.