Essential Hospital Bed Accessories List

hospital bed accessories can greatly improve comfort and safety. Here’s a list of important items to consider:

Hospital Bed Side Rails

Overbed Tables

Hospital Bedside Cabinets

IV Pole

Medical Mattresses

Pressure Relief Mattresses

Night Light

Patient Call Button

These hospital bed accessories enhance both comfort and safety, improving the overall hospital bed experience for patients.

hospital bed accessories

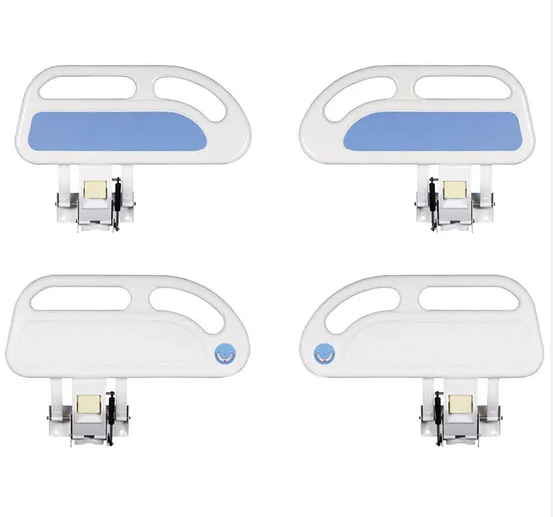

Hospital Bed Side Rails

Hospital bed side rails as hospital bed accessories improve patient safety and comfort. They provide support, help prevent falls, and make it easier for patients to shift positions. It feels like having a steady hand nearby, offering a firm grip when needed.

Benefits of Hospital Bed Side Rails

- Prevents Falls: Bed side rails reduce the risk of falls, particularly for patients who may be confused, weak, or recovering from surgery.

- Supports Mobility: Side rails give patients something to hold onto while they move or shift in bed, making it easier and less strenuous.

- Improves Caregiver Efficiency: Bed side rails help caregivers assist patients more effectively by providing additional support when adjusting their position.

- Enhances Comfort: With a stable grip and added security, patients feel more comfortable and confident in bed, improving their overall care experience.

Hospital Overbed Tables

Overbed tables are a great addition to your space. They as hospital bed accessories provide comfort and convenience exactly where you need them. You can enjoy a meal, read a book, or use your device with ease. This solid surface becomes your personal space to relax. For those who are bedridden, it’s not just furniture—it’s a helpful tool, keeping everything within reach without unnecessary movement.

Height-Adjustable Features

Many overbed tables have adjustable heights. They range from 28 to 45 inches, allowing users to find a comfortable position. This flexibility benefits patients of different sizes and needs, making the table useful whether sitting or lying down.

Hospital Bedside Cabinets

Hospital bedside cabinets are essential in patient care. They keep everything you need close by. Personal items and medical supplies can be easily organized, which helps you stay comfortable and focused. These cabinets make the room look tidier and improve the overall efficiency. They help make your hospital stay more pleasant.

Benefits of Hospital Bedside Cabinets

- Convenient Storage – Patients can easily store medications, personal belongings, and other necessary supplies.

- Better Hygiene – Many cabinets are made of materials that are easy to clean, helping maintain a sterile environment.

- Increased Comfort – Having essential items nearby reduces patient stress and enhances their experience.

- Durability – Made with strong materials, these cabinets are built to withstand daily hospital use.

Features to Consider

- Material – Choose from stainless steel, ABS plastic, or wood options for strength and hygiene.

- Mobility – Some cabinets have wheels for easy movement.

- Lockable Drawers – Provides extra security for personal and medical items.

- Multi-Compartment Design – Helps organize various types of supplies with ease.

Choosing the Right Bedside Cabinet

Choosing the right cabinet depends on the hospital’s needs and the patient’s requirements. Consider factors like size, storage capacity, and material to ensure it’s functional and easy to use.

IV Pole

An IV pole plays a crucial role in a hospital room. It stands by, helping fluids flow during treatment. It holds everything in place and allows the medical team to manage IV lines and medications. Without it, maintaining care would be much harder.

Benefits of an IV Pole

- Reliable Support: Holds IV bags and pumps in place to prevent accidental removal.

- Better Mobility: Lets patients move more easily while receiving treatment.

- Eases Caregiving: Reduces strain by keeping medical equipment stable.

- Keeps Things Organized: Helps maintain a clean setup, making IV lines and supplies easy to access.

With its adjustable design, an IV pole improves patient comfort and makes medical procedures more efficient.

Medical Functional Mattresses

Imagine lying on a mattress that feels like a soft cloud. The palm fiber and sponge combination provides just the right mix of support and comfort. It gently relieves pressure, letting you relax, while the smart design helps keep you cool by allowing air to flow easily. This is especially for those who spend long periods in bed. It helps prevent discomfort and issues like heat buildup and bedsores, allowing you to rest peacefully.

Benefits of Medical Mattresses

- Firm Support: Keeps the body properly aligned and reduces pressure points.

- Pressure Relief: Prevents pressure ulcers and bedsores.

- Durability: Built to last through extended use while maintaining performance.

- Hygiene & Maintenance: Easy to clean and maintain for better hygiene.

- Comfort: The mix of palm fiber and sponge offers comfort for long periods of use.

Pressure Relief Mattresses

Pressure relief mattresses help improve comfort and prevent bedsores, making them ideal for people who spend long hours in bed. They reduce pressure on the body and improve circulation, which is crucial for those with limited mobility.

Benefits of Pressure Relief Mattresses

- Prevents Bedsores: These mattresses use memory foam or air cells to ease pressure on sensitive areas, lowering the risk of sores.

- Customizable Comfort: Many models let users adjust firmness and temperature to match their needs.

- Better Support: They evenly distribute body weight, increasing comfort and reducing strain from lying down too long.

Night Light

A night light is a key accessory for Hospital Beds that boosts patient safety and comfort. It helps prevent falls in low-light settings, allowing patients to move safely at night. The soft light also lets caregivers monitor patients without waking them, making it useful for both patients and staff.

Key Benefits:

- Safety: Low light reduces the risk of falls in the dark.

- Convenience: Caregivers can check on patients without disturbing them.

- Energy-efficient: Uses minimal power, making it cost-effective and eco-friendly.

- Easy Installation: Easy to set up with no major changes needed to the bed setup.

Patient Call Button

A patient call button is an important part of Hospital beds, helping improve patient safety and comfort. It lets patients easily communicate with medical staff, making sure they get help when needed. This reduces response times in emergencies, improving both patient care and hospital efficiency.

Key Benefits of a Patient Call Button

- Better Communication: Allows patients to ask for help anytime, reducing stress and worry.

- Increased Safety: Helps patients alert medical staff quickly in emergencies.

- More Comfort: Gives patients peace of mind, knowing help is just a button away.

- Faster Response Times: Cuts down on delays in medical response, which is crucial in urgent situations.

A well-designed call button system makes sure patients are not left alone and can stay independent while receiving the best care.

Summary

If you need to find a reliable hospital bed manufacturer and accessories provider, Grace Medy is a good choice.Grace Medy provides one-stop hospital furniture matching services, not only hospital beds, but also various accessories for hospital beds, as well as hospital chairs, emergency carts, operating tables, operating lights, stretchers, Wheelchairs ,walking aids and other hospital furniture and rehabilitation equipment.

Using the right accessories for a hospital bed improves patient care. Side rails, pressure relief mattresses, and other items enhance comfort, safety, and well-being. As healthcare advances, patients need quality accessories to support recovery and improve their experience. Every detail helps create a better healing environment.